Trace Heating Introduction

Electric trace heating is the application of a compensating heat source used to temperature maintain or raise pipes, surfaces and vessels.

Trace heating cable replaces the losses of heat from a surface to allow temperature maintenance of a product, which thermal insulation alone can not maintain.

Trace heating can be used to protect pipes from freezing (Frost Protection), maintain the temperature of a hot water system (Hot Water Temperature Maintenance), or maintain process temperatures for smooth and efficient running of process plant equipment (Process Temperature Maintenance).

Heat trace systems can be categorised into four main installation areas:

- Domestic

- Commercial

- Industrial

- Hazardous

Economy domestic trace heating

These heating cables are designed to meet the ‘economy‘ requirements of simple frost protection systems where cost is a major factor.

These heating cables are designed to meet the ‘economy‘ requirements of simple frost protection systems where cost is a major factor.

Domestic application include the frost protection of the following:

- External taps & pipework

- Sprinkler pipework

- Condenser boilers

- Outbuilding, sheds, stables

- Farm buildings

- Utility rooms

- Garages

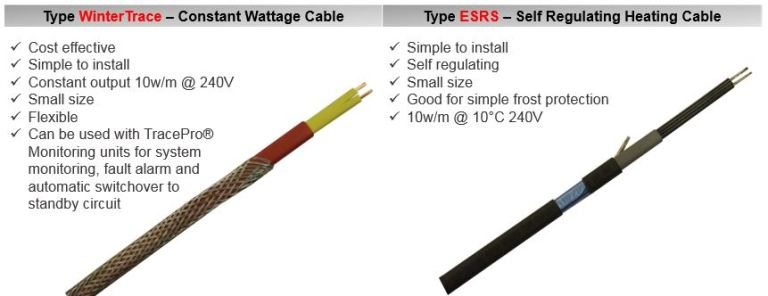

- Static caravans

Both constant wattage and self regulating heating tape systems perform excellently for use within frost protection applications.

Commercial Trace Heating

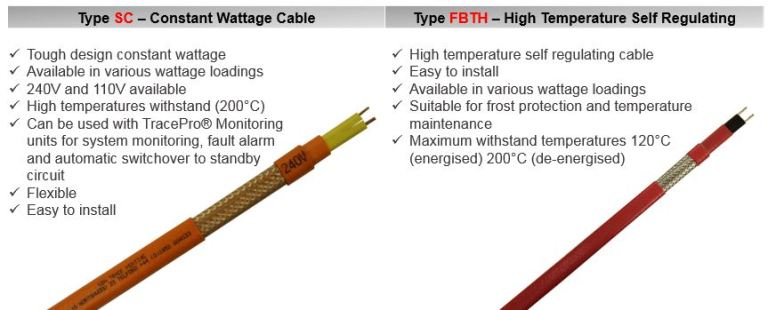

Our most commonly used heating cables. Designed for frost protection and temperature maintenance of commercial and industrial pipework and vessels.

Applications include:

- Internal & external frost protection to commercial areas

- Process temperature maintenance

- Hot water temperature maintenance

- Oil & chemical lines

- Sprinkler system mains

- Supply piping

Industrial Trace Heating

Designed to meet the higher demands placed upon trace heating cables within industrial areas. These though cables can provide frost protection or process temperature maintenance of industrial pipework and vessels.

Designed to meet the higher demands placed upon trace heating cables within industrial areas. These though cables can provide frost protection or process temperature maintenance of industrial pipework and vessels.

Application include:

- Internal & external frost protection to industrial areas

- Process temperature maintenance

- Oil & chemical lines

- Supply piping

Hazardous Area Trace Heating

A hazardous area location is defined as a place where concentrations of flammable gases, vapors, or dust occur.

A hazardous area location is defined as a place where concentrations of flammable gases, vapors, or dust occur.

Electrical equipment that must be installed in such locations are specifically designed and tested to ensure they do not initiate an explosion, due to arching contacts or high surface temperatures.

Our ATEX Approved heating cables are suitable for internal and external frost protection and temperature maintenance within Zone I & Zone II Explosive Atmospheres.

If you have a specific design requirement or need advice on your present or future heat trace applications, please contact us